절연조인트(Insulation joint)

개요 및 적용범위

- 신설 배관과 기존관(전기방식 조치를 취하지 않은 배관)과의 절연 및 신규 가정관의 절연을 목적으로 사용한다.

- 공급관 교체공사구간 ,루프화 공사구간, 절연 밸브실을 설치하지 않는 기존 공급관의 절연을 위해 사용한다.

- 전기장치와 연결 또는 인접된 가스성 각종 유체기기의 손상 방지용

- 정진기 및 낙뢰로 인한 가스 폭발 위험이 있는 배관의 전기적 보호

- 절연배관 시공 여건상 사후 유지보수관리가 어려운 조건일 때

제품의 특성

- 견고한 내부구조로 외부 충격 및 온도변화에 따른 안전성을 보장 합니다. (발명특허 0538562)

- 내부구조의 Seeling은 2중구조의 O-Ring을 채택함으로서 외부의 최악의 조건에서도 견딜수 있는 구조입니다.

- 시공 후 별도의 절연조치가 필요치 않은 조인트의 외부를 E.P.X Coatting을 함으로서 외부노출 및 매몰 시에도 최적의 절연성을 유지하며, 외부 충격에도 강하여 반영구적으로 절연성 및 구조의 변화 없이 사용할 수 있습니다.

- 복원력(외부 열 변화 및 지반 침하로 인한 악조건) 및 내열성(시공 시 용접 열 및 자연 온도 변화의 조건)에 강한 재질의 O-Ring을 사용하였습니다.

- INSULATION JOINT 은 한번 설치가 되면, 매설이 가능하고, 유지보수를 필요 없게 됩니다.

이점 & 장점

- 일반적인 열팽창이나 지면 스트레스(ground stress)로 인한 안전성의 손실은 없습니다.

- 1.5배에 해당하는 운전 압력으로 공장에서, 유체 정역학으로 그리고 전기적으로 테스트를 거쳐고 비-파괴적인 테스트를 이용할 수 있습니다.

- 컴프레셔 스테이션(compressor station)과 같이 요구되는 절연 공식(application)에서 유지보수를 필요로 하지 않으며, 장비의 음극 절연을 신뢰할 수 있습니다.

- 비-노동집약적이며, 절연 개스킷 키트와 마찬가지로 설치 절차가 복잡하지 않습니다.

- 검사 피트, 볼트 또는 유지보수를 필요로 하지 않으며 적절하게 용접이 되어, 직접적으로 매립이 가능하며 음극 절연을 신뢰할 수 있어 그에 대한 걱정이 없습니다.

- 외부적으로 그리고 내부적으로, 단선을 방지하는데 도움이 되는 비-전도 에폭시 코팅이 되어있습니다.

- 전기 전달 시스템, 지전류(earth current) 그리고 포인트에서 포인트로 흐르는 전류와 같이 외부 압력에서 파이프에 발생한 표류 전류를 고립시킵니다.

- 우수한 굽힘(bending) 및 비틀림 저항를 가지고 있습니다.

비용 절약 장점

- 일체형 조인트가 플랜지 절연 가스켓 키트보다 비용 면에서 효률적 입니다. 소재, 노동 집약적 설치, 프리-온라인(pre-online) 검사 및 연속적인 유지보수는 물론 가스겟 키트의 교체는 음극 절연에서 INJOINTⓡ을 매우 효과적이고 효율적인 방법입니다.

적용

- 기존 그리고 새로운 구조

- 가스, 석유, 액체 석유화학 및 흘수선(water line)

- 가스 분포 스테이션(distribution station) 이전, 그리고 가스 분포 스테이션.

- 가스 또는 액체 연료 탱크.

- 지하 또는 지상 사용

전기적 속성

- 최고 품질의 절연 소재

- 1분 동안 내압테스트 전압 3kV(50.60㎐)에서(sparking breakdown) 이상 없음

- 건조 조건의 DC 1kV 전압에서 5MΩ 이상의 절연 저항 이상 없음

- 수압 테스트(사용압력의 1.5배) 60분동안 이상 없음

절연 조인트의 기본 데이타

ANSI 150 (PN25)

- 최대 운전 압력, 25kg/㎠(2.5Mpa)

- 강도 테스트에 관한 압력, 37,5kg/㎠ (3.75Mpa)

- 운전 온도 범위 TS, -28~80°c (℉-22~176°)

- 1분(건조 조건에서) AC 전기 전압 3kV(50.60㎐)

- DC 전압 1kV에서 저항(건조 조건에서)5,0 MΩ~25.0 MΩ

ANSI 300 (PN65)

- 최대 운전 압력, 30kg/㎠ (3.0Mpa)

- 강도 테스트에 관한 압력, PT, 45kg/㎠ (4.5Mpa)

- 운전 온도 범위 TS,-28~80°c (℉-22~176°)

- 1분(건조 조건에서) AC 전기 전압 3kV(50.60㎐)

- DC 전압 1kV에서 저항(건조 조건에서)5,0 MΩ~25.0 MΩ

ANSI 600 (PN100)

- 최대 운전 압력, 70kg/㎠ (7.0Mpa)

- 강도 테스트에 관한 압력, PT, 105kg/㎠ (10.5Mpa)

- 운전 온도 범위 TS,-28~80°c (℉-22~176°)

- 1분(건조 조건에서) AC 전기 전압 3kV(50.60㎐)

- DC 전압 1kV에서 저항(건조 조건에서)5,0 MΩ~25.0 MΩ

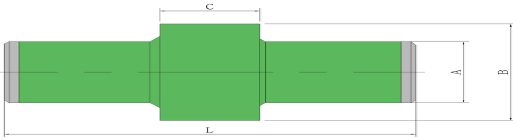

제품구조

| NO | Description | Materal |

| 1 | Right pipe | KSD 3562 / Apl 5L B / SUS |

| 2 | Left pipe | KSD 3562 / Apl 5L B / SUS |

| 3 | Center Guide | ASTM A106 / A 694 F42외 / SUS |

| 4 | Insu Sheet | ENG Nylon |

| 5 | Insu Guide | ENG Nylon |

| 6 | Seal O-Ring | N.B.R / VETON-O-RING |

| 7 | Coating | Epoxy |

| SIZE | 150/300# (1.0-4.0Mpa) | 600# (4.0-7.0Mpa) | |||||||||

| A | B | C | L | Welght | A | B | C | L | Welght | ||

| 3/4" | 20A | 27.2 | 55 | 50 | 280 | 1.9kg | 26.7 | 74 | 70 | 350 | 2.0kg |

| 1" | 25A | 34.0 | 60 | 57 | 280 | 2.0kg | 33.4 | 76 | 70 | 390 | 2.5kg |

| 1 1/4" | 32A | 42.7 | 70 | 57 | 285 | 2.7kg | 42.2 | 90 | 75 | 400 | 3.2kg |

| 1 1/2" | 40A | 48.6 | 76 | 57 | 290 | 3.0kg | 48.3 | 118 | 80 | 420 | 3.7kg |

| 2" | 50A | 60.5 | 88 | 58 | 385 | 3.5kg | 60.3 | 125 | 85 | 450 | 4.9kg |

| 2 1/2" | 65A | 76.3 | 109 | 60 | 395 | 7.0kg | 73.0 | 130 | 90 | 450 | 8.5kg |

| 3" | 80A | 89.1 | 125 | 76 | 405 | 10kg | 88.9 | 150 | 100 | 450 | 15kg |

| 4" | 100A | 114.3 | 150 | 77 | 415 | 19kg | 114.3 | 190 | 130 | 500 | 25kg |

| 5" | 125A | 139.8 | 175 | 80 | 440 | 35kg | 141.3 | 235 | 140 | 550 | 45kg |

| 6" | 150A | 165.2 | 216 | 95 | 445 | 50kg | 168.3 | 260 | 150 | 600 | 58kg |

| 8" | 200A | 216.3 | 267 | 100 | 550 | 65kg | 219.1 | 315 | 160 | 600 | 75kg |

| 10" | 250A | 267.4 | 324 | 120 | 630 | 85kg | 273 | 375 | 200 | 750 | 90kg |

| 12" | 300A | 318.5 | 400 | 140 | 755 | 120kg | 323.8 | 430 | 220 | 800 | 180kg |

| 14" | 350A | 355.6 | 457 | 140 | 800 | 140kg | 355.6 | 455 | 230 | 900 | 205kg |

| 16" | 400A | 406.4 | 508 | 150 | 800 | 165kg | 406.4 | 565 | 300 | 1.000 | 250kg |

| 18" | 450A | 457.2 | 555 | 160 | 800 | 300kg | 457.2 | 605 | 330 | 1.000 | 340kg |

| 20" | 500A | 508.0 | 603 | 160 | 800 | 350kg | 508.0 | 655 | 370 | 1.000 | 480kg |

| 24" | 600A | 610.0 | 750 | 190 | 1.000 | 600kg | 609.6 | 750 | 400 | 1.100 | 710kg |

※ 주문 시 다음을 명시해주시기 바랍니다.

- 1. 파이프의 직경

- 2. ANSI.API.KS.JIS 등급

- 3. 파이프 소재의 등급

- 4. 유체의 내용

- 5. 비파괴 검사.NDT(UT.RT.MT.PT)

KS Q IS09001:2009 / ISO9001:2008:2001 / ISO 9001:2001인증업체

- 발명특허: No 0538562

- 의장등록: No 146862

- 실용신안: No 078282

- CERTIFICATE OF PAYENT :No 0538562

- CERTIFICATE OF PAYENT :No 2002-0058222

Abstract and Scope of application

- Used for insulations between a new chamber pipe and an existing pipe, and the new chamber pipe and a new pipe for home.

- Used for insulations between a section for the construction of replacing a supplying pipe, a section for the formation of a loop, and an existing supplying pipe without an insulated valve chamber.

- Used for the prevention of a damage to equipments of various kinds which are connected or adjacent to an electrical apparatus.

- Used for the electrical protection of a pipe with may be exposed to a denger of gas explosion due to static electricity and thunderbolt.

- sed when there is provided a condition where is in difficulties for expost facto maintenance and repair, considering a given condition for the construction of an insulation pipe.

Abstract and Scope of application

- It guarantees safety form an impact form the outside and change of temperature on account of it"s strong internal structure. (patent 0538562)

- Sealing of an internal structure adopting an O-Ring of a dual structure is durable even under the worst condition wherein materials for the O-Ring arecharacteristic of strong restitution force(under a condition due to the chang of welding heat and natural temperature at the time of construction)

- By performing F.R.P and EPX Coatting for the outside of a joint for which operation of special insulation is unnecessary after construction, optimal insulation is maintained even at the time of the exposure of the outside and a burying and the strong resistance of an external inpact is exercised to thereby use a product semi-permanently without changes of insulation and structure

IsoJoint

-

IsoJoint is a true monolithic isolating joint which effectively and effciently stops short circuits and stray currents from damaging pipelines and equipment.

IsoJoint employs one or more, preassembled pressure seals and isolating ring, Unlike isolating gasket kits, lsoJoint does net depend on an installer fitting gasket, sleeves and washers into a flange on loaction, Any one of these pates could be damaged causing a complete breakdown of the isolated flange, thus loosiing cathodic isolation. because IsoJoint are welded into place as one piece units, field problems are virtually non-existent and integrity of the isolation is kept intact. -

Furthermore, once installed, IsoJoint can be buried and forgotten ending your maintenance worries.

In contrast,inspections of above ground isolation gaskets are necessary to check for shorts in the gaskets.This requires a continuing maintenace program during the entire life of the pipeline.

BENEFITS & ADVANTAGES

-

In-factory tested hydrostatically and electrically, to 1 1/2 times their working pressure.

Non-destructive testing is also avallable.

No labor intensive, complicated installation procedure required as with isolation gasket kits - No inspection pits, vaults or maintenance needed-weld into place and direct bury-reliable, worry-free cathodic isolation.

- Non-conductive epoxy coatings help prevent shorts,both externally and internally

- Isolates stray currents impressed on the pipe from exterior forces such as electrical transmission systems,earth currents and currents flowing from point to point

- Earthquake resistant -Acts as a thrust block or joint

ADVANTAGE IN SAVINGS

- The notion that flange isolation gasket kits are more cost efficient than monolithis joints is not well supported when figuring in all the variables.

APPLICATIONS

- On gas,oil,liquid pertrochemical and water lines

- Before and from gas distribution stations

- On gas or overground usage

- Under or overgrounf usage

Mechanical properties

- Bodies of monolithic joints are made as rolled and welded construction of steel sheet of forged bodies

- All test results are available

Electrical propertise

- Highest quality isolation materials

- No sparking breakdown during 1minute hydrostatic testing

- Isoting resistance above 5,0 MΩ~25.0 MΩ at voltage DC 1kv in dry conditions -standard, higher voltage resistance available

- No breakdown during pressured leak testing

Basic Parameters Of Insulating joints

- Bodies of monolithic joints are made as rolled and welded construction of steel sheet of forged bodies

- All test results are available

ANSI 150(PN25)

- Maximum Operating Pressure, 25kg/㎠(2.5Mpa)

- Pressure of Strength Test, PT,37.5kg/㎠(3.75Mpa)

- Working Temperature Range TS -28~80°c (℉-22~176°)

- Electrical voltage AC 3kV(60Hz) in 1 min. time(in dry condition)

- Resistance at voltage DC 1kV(in dry condition) 5,0 MΩ~25.0 MΩ

ANSI 300(PN65)

- Maximum Operating Pressure, 30kg/㎠ (3.0Mpa)

- Pressure of Strength Test, PT, 45kg/㎠ (4.5Mpa)

- Working Temperature Range TS -28~80°c (℉-22~176°)

- Electrical voltage AC 3kV(60Hz) in 1 min. time(in dry condition)

- Resistance at voltage DC 1kV(in dry condition) 5,0 MΩ~25.0 MΩ

ANSI 600(PN100)

- Maximum Operating Pressure,70kg/㎠ (7.0Mpa)

- Pressure of Strength Test, PT,105kg/㎠ (10.5Mpa)

- Working Temperature Range TS -28~80°c (℉-22~176°)

- Electrical voltage AC 3kV(60Hz) in 1 min. time(in dry condition)

- Resistance at voltage DC 1kV(in dry condition) 5,0 MΩ~25.0 MΩ